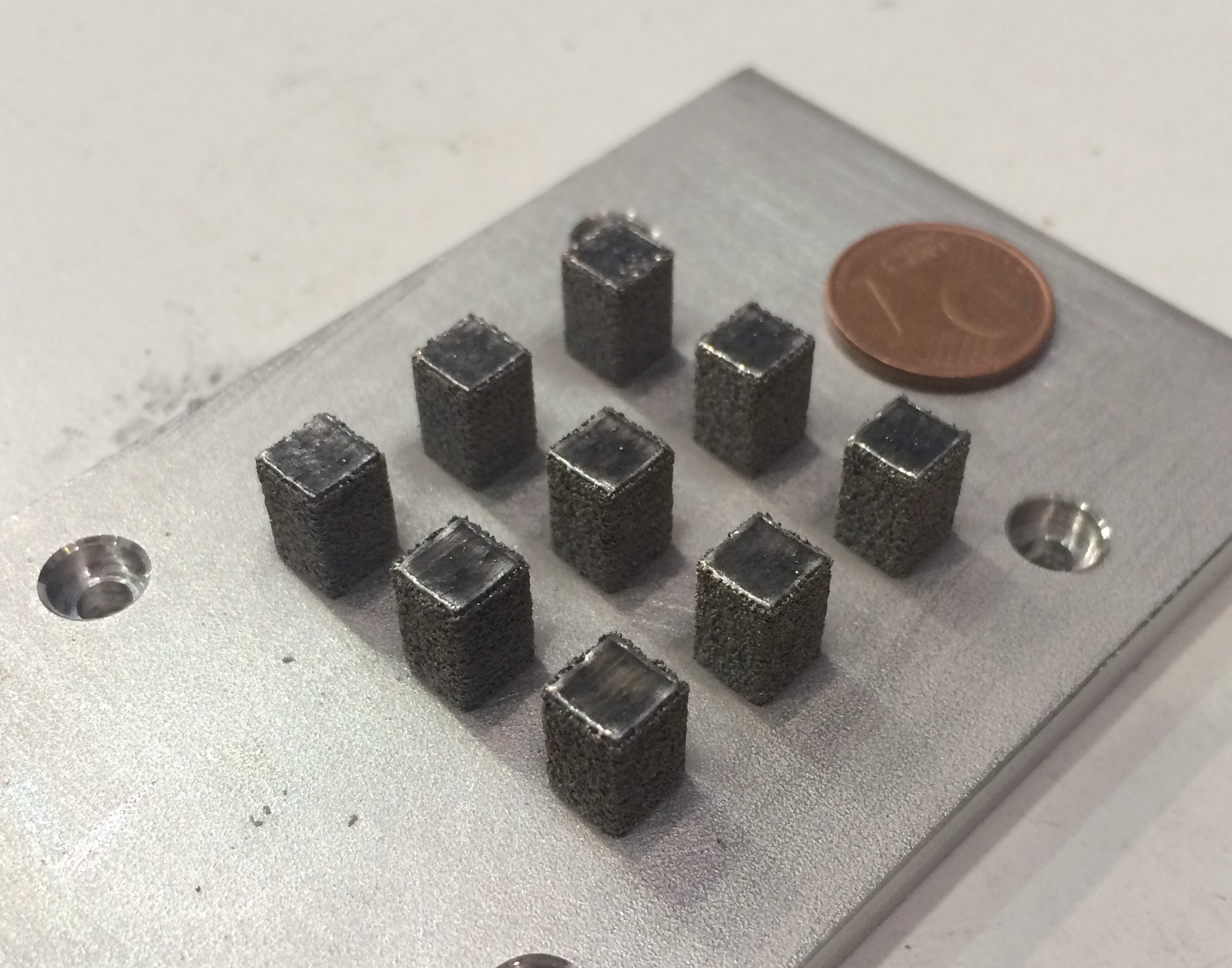

The aim of the project is to draw the next frontiers of cold spray (CS), a new, solid-state coating deposition technology. At first, the process and its advantages and disadvantages have been assessed. Then, current equipment, materials and applications have been studied, in order to outline present technological limits from the study of recent innovations in the field. Subsequently, cold spray technical, environmental and economic impact in comparison with competing processes (thermal coatings, additive manufacturing technologies) have been analysed. At this point, the explorative phase of the project began, and new innovative applications, promising materials systems and technological improvements have been investigated and selected. Indeed, the project focused on developing four high-potential applications in four different fields, and on assessing both their technical and economical feasibility. First of all, three different demonstrators produced with CS technology were developed in biomedical, additive manufacturing (AM) and materials fields respectively. Regarding the biomedical demonstrator, properties of titanium-silver-hydroxyapatite (Ti-Ag-HA) coatings have been studied in order to be deposited on a tibial prosthesis, aiming at both reducing post-surgery infection probability and increasing cellular adhesion to the implant. For what concerns additive manufacturing, CS potentialities have been assessed by comparing CS sprayed specimens with samples produced with Selective Laser Melting (SLM) technology. Regarding the materials field, a thick coating of amorphous metal has been deposited. Finally, the fourth application consisted in optimizing nozzle geometry to increase CS deposition efficiency. This has been achieved through the creation of a model able to describe and simulate the flow throughout the nozzle, thus enabling the design of a new nozzle. In conclusion, technical performance assessment of CS, compared to other thermal and additive technologies, has been accomplished, in addition to economical feasibility study focused on the biomedical and additive manufacturing applications. A final critical assessment of CS opportunities evidenced how CS impacts the entire value chain and compared the results with present processes.

The aim of the project is to draw the next frontiers of cold spray (CS), a new, solid-state coating deposition technology. At first, the process and its advantages and disadvantages have been assessed. Then, current equipment, materials and applications have been studied, in order to outline present technological limits from the study of recent innovations in the field. Subsequently, cold spray technical, environmental and economic impact in comparison with competing processes (thermal coatings, additive manufacturing technologies) have been analysed. At this point, the explorative phase of the project began, and new innovative applications, promising materials systems and technological improvements have been investigated and selected. Indeed, the project focused on developing four high-potential applications in four different fields, and on assessing both their technical and economical feasibility. First of all, three different demonstrators produced with CS technology were developed in biomedical, additive manufacturing (AM) and materials fields respectively. Regarding the biomedical demonstrator, properties of titanium-silver-hydroxyapatite (Ti-Ag-HA) coatings have been studied in order to be deposited on a tibial prosthesis, aiming at both reducing post-surgery infection probability and increasing cellular adhesion to the implant. For what concerns additive manufacturing, CS potentialities have been assessed by comparing CS sprayed specimens with samples produced with Selective Laser Melting (SLM) technology. Regarding the materials field, a thick coating of amorphous metal has been deposited. Finally, the fourth application consisted in optimizing nozzle geometry to increase CS deposition efficiency. This has been achieved through the creation of a model able to describe and simulate the flow throughout the nozzle, thus enabling the design of a new nozzle. In conclusion, technical performance assessment of CS, compared to other thermal and additive technologies, has been accomplished, in addition to economical feasibility study focused on the biomedical and additive manufacturing applications. A final critical assessment of CS opportunities evidenced how CS impacts the entire value chain and compared the results with present processes.

Principal Academic Tutor

Mario Guagliano, Department of Mechanical Engineering, Politecnico di Milano

Academic Tutors

Monica Ferraris, Department of Applied Science and Technology, Politecnico di Torino

Alberto Guardone, Department of Aerospace Engineering, Politecnico di Milano

Barbara Previtali, Department of Mechanical Engineering, Politecnico di Milano

Chiara Vitale Brovarone, Department of Applied Science and Technology, Politecnico di Torino

Sara Bagherifard, Department of Mechanical Engineering, Politecnico di Milano

External institutions

Impact Innovation GmbH (Haun, D)

Helmut Schmidt University (Hamburg, D)

Technical University of Brno (Brno, CZ)

Centre de Projecció Térmica (CPT) – Universitat de Barcelona (Barcelona,E)

University of Nottingham (Nottingham, UK)

External Tutors

Peter Ricther, Sr. , Impact Innovations GmbH

Professor Frank Gaertner, Helmut Schmidt University

Jan Cizek, Technical University of Brno

Josep Maria Guilemany, Centre de Protecció Térmica (CPT) – Universitat de Barcelona

Tanvir Hussain, University of Nottingham

Team members

Paolo Caputo, Space Engineering, Politecnico di Milano

Gaetano D’Elia, Mechanical Engineering, Politecnico di Torino

Martina Genta, Biomedical Engineering, Politecnico di Torino

Mehdi Hadi, Mechanical Engineering, Politecnico di Torino

Fabio Pino, Space Engineering, Politecnico di Torino

Gianluca Roscioli [Team Controller and Communication Coordinator], Material and Nanotechnology Engineering, Politecnico di Milano

Maria Vittoria Zuccoli, Mechanical Engineering, Politecnico di Milano